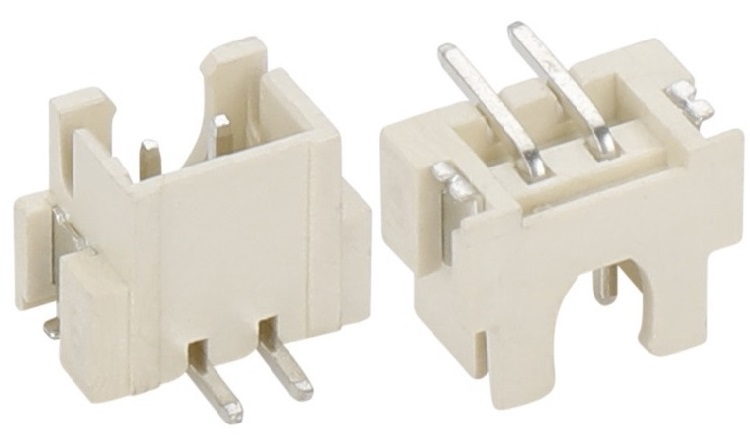

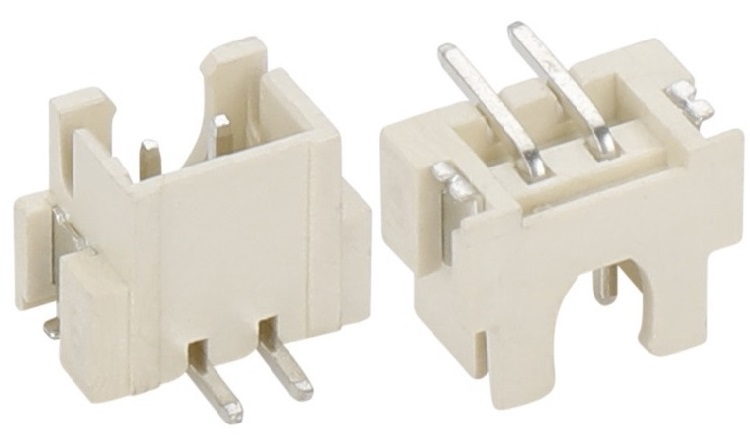

产品名称:针座2.0间距

规格:

额定电流:2.0A AC,DC

额定电压:100V AC、DC

温度额定值:-25℃~+85℃

绝缘电阻:最小1000M52。

耐压:800V AC/分钟

接触电阻:20m52/最大

材料:

外壳:尼龙66,UL94V-2

引脚:黄铜/镀锡

触点:磷青铜

产品符合:ROHS

品牌:科斯达开关 KSDKG

产地:中国东莞

针座2.0间距是一种常见的电子元器件连接标准,主要用于电路板上的焊接和连接。其特点包括:

1.标准化设计:2.0间距是国际上比较常见的引脚间距,使得各种元器件可以互换和兼容。

2.提高密度:与其他间距相比,2.0间距在保持可靠连接的基础上,可以在有限的空间内实现较高的元件密度。

3.易于焊接:2.0间距的引脚设计使得焊接过程相对简单,适合手工焊接和自动化生产。

4.电气性能佳:较小的间距能够减少信号干扰,提高电路的整体性能。

5.适用范围广:广泛应用于各种电子产品中,如家电、通信设备、计算机等。

6.可靠性:良好的机械强度和防护设计,确保连接的可靠性和长期使用稳定性。

7.适应性强:适用于不同类型的插座、连接器和其他电子元器件。

这些特点使得针座2.0间距成为许多电子设计中流行的选择。

线对板连接器(Wire-to-Board Connector)是一种用于将电缆线连接到电路板上的连接器,常见于电子设备中。2.0mm连接器是此类连接器的一种,通常用于较小的电子产品,由于其相对较小的间距,可以节省空间。

2.0mm线对板连接器的主要特点:

1.间距:每个连接器的引脚间距为2.0mm。

2.应用广泛:广泛应用于消费电子、工业控制、家用电器等领域。

3.多种类型:可以是单排或双排引脚,根据具体需求选择。

4.耐用性:一般具有良好的抗振性和耐腐蚀性。

5.电气性能:支持一定的电流和电压,具体参数需根据产品规格来选择。

选择时需考虑的因素:

1.材料:通常需要考虑插头和插座的材料,是否合适环境要求。

2.额定电流和电压:确保连接器符合使用条件。

3.接触类型:焊接或插拔类型,取决于设计需求。

4.安装方式: PCB安装方式(如立式、插入式等)。

针座2.0间距通常指的是在电子元器件中,针脚之间的中心距为2.0毫米。这种间距常用于各种连接器、集成电路和其他器件的封装设计中。具体描述可能包括以下几点:

1.规格:针座的每个针脚之间的中心距离为2.0毫米,适合需要小间距布局的电路设计。

2.应用:广泛应用于导线连接、PCB(印刷电路板)连接、传感器接口等领域。

3.兼容性:确保与其他2.0间距的连接器可以互换使用,便于设计和整合。

4.特点:针脚设计可能包括金属镀层以提高导电性及耐用性。

5.封装类型:可以是直插式、表面贴装等多种形式,根据具体应用需求选择。

Product Name: Needle Seat 2.0 Spacing

Specifications:

Rated current: 2.0A AC, DC

Rated voltage: 100V AC, DC

Temperature rating: -25 ℃~+85 ℃

Insulation resistance: minimum 1000M52.

Voltage resistance: 800V AC/min

Contact resistance: 20m52/maximum

Material Science:

Shell: Nylon 66, UL94V-2

Pin: brass/tin plated

Contact: phosphor bronze

Product compliance: ROHS

Brand: Coaster Switch KSDKG

Origin: Dongguan, China

Pin holder 2.0 spacing is a common electronic component connection standard, mainly used for soldering and connection on circuit boards. Its characteristics include:

1. Standardized design: 2.0 pitch is a common pin spacing internationally, allowing various components to be interchangeable and compatible.

2. Increase density: Compared with other spacing, 2.0 spacing can achieve higher component density in limited space while maintaining reliable connections.

3. Easy to solder: The 2.0 pitch pin design makes the soldering process relatively simple, suitable for manual soldering and automated production.

4. Excellent electrical performance: A smaller spacing can reduce signal interference and improve the overall performance of the circuit.

5. Wide applicability: Widely used in various electronic products, such as household appliances, communication equipment, computers, etc.

6. Reliability: Good mechanical strength and protective design ensure the reliability and long-term stability of the connection.

7. Strong adaptability: Suitable for different types of sockets, connectors, and other electronic components.

These features make the needle hub 2.0 spacing a popular choice in many electronic designs.

A wire to board connector is a type of connector used to connect cable wires to circuit boards, commonly found in electronic devices. The 2.0mm connector is a type of connector that is typically used for smaller electronic products. Due to its relatively small spacing, it can save space.

The main features of the 2.0mm wire to board connector are:

1. Spacing: The pin spacing of each connector is 2.0mm.

2. Wide application: Widely used in consumer electronics, industrial control, household appliances and other fields.

3. Multiple types: can be single row or double row pins, choose according to specific needs.

4. Durability: Generally has good vibration resistance and corrosion resistance.

5. Electrical performance: Supports a certain current and voltage, specific parameters need to be selected according to product specifications.

Factors to consider when choosing:

1. Materials: It is usually necessary to consider whether the materials of plugs and sockets are suitable for environmental requirements.

2. Rated current and voltage: Ensure that the connector meets the usage conditions.

3. Contact type: Welding or plug-in type, depending on design requirements.

4. Installation method: PCB installation method (such as vertical, plug-in, etc.).

Pin holder 2.0 spacing usually refers to a center to center distance of 2.0 millimeters between pins in electronic components. This spacing is commonly used in the packaging design of various connectors, integrated circuits, and other devices. The specific description may include the following points:

1. Specification: The center distance between each pin of the needle holder is 2.0 millimeters, suitable for circuit designs that require small spacing layouts.

2. Application: Widely used in wire connections, PCB (printed circuit board) connections, sensor interfaces, and other fields.

3. Compatibility: Ensure that it can be interchanged with other 2.0 pitch connectors for easy design and integration.

4. Features: Pin design may include metal plating to improve conductivity and durability.

5. Packaging type: It can be in various forms such as direct insertion, surface mount, etc., depending on specific application requirements.