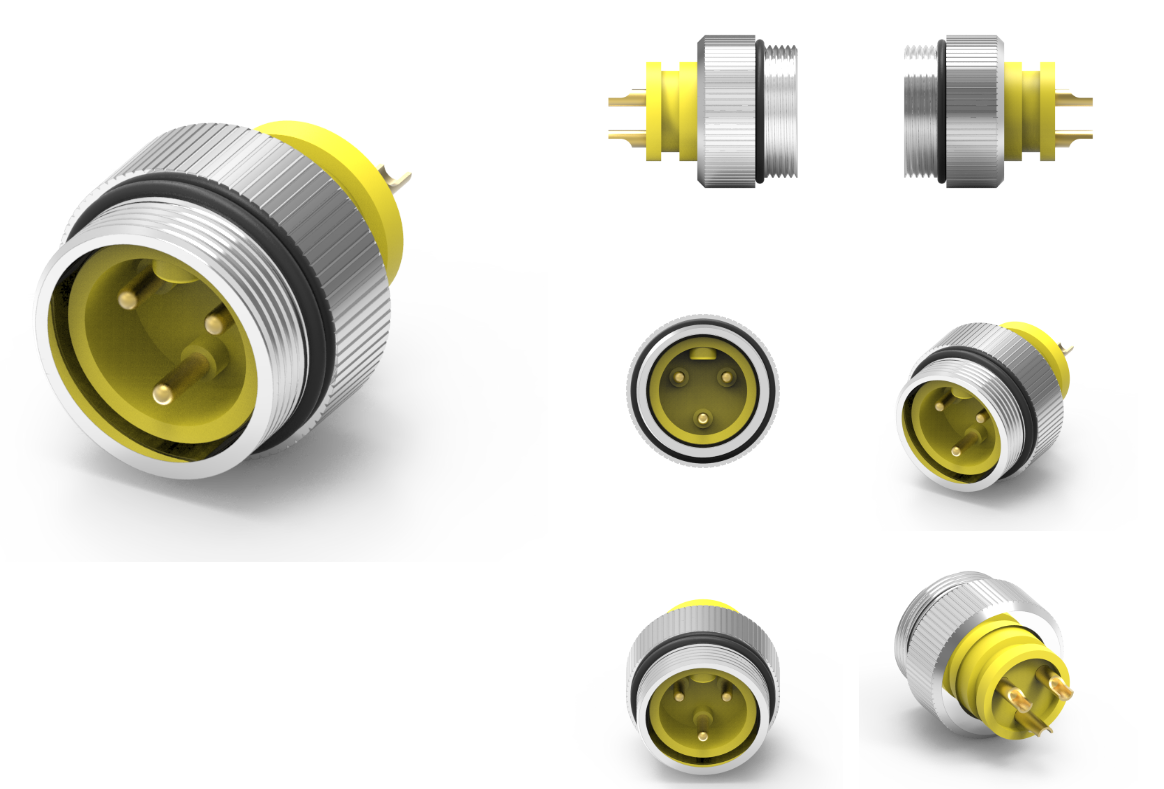

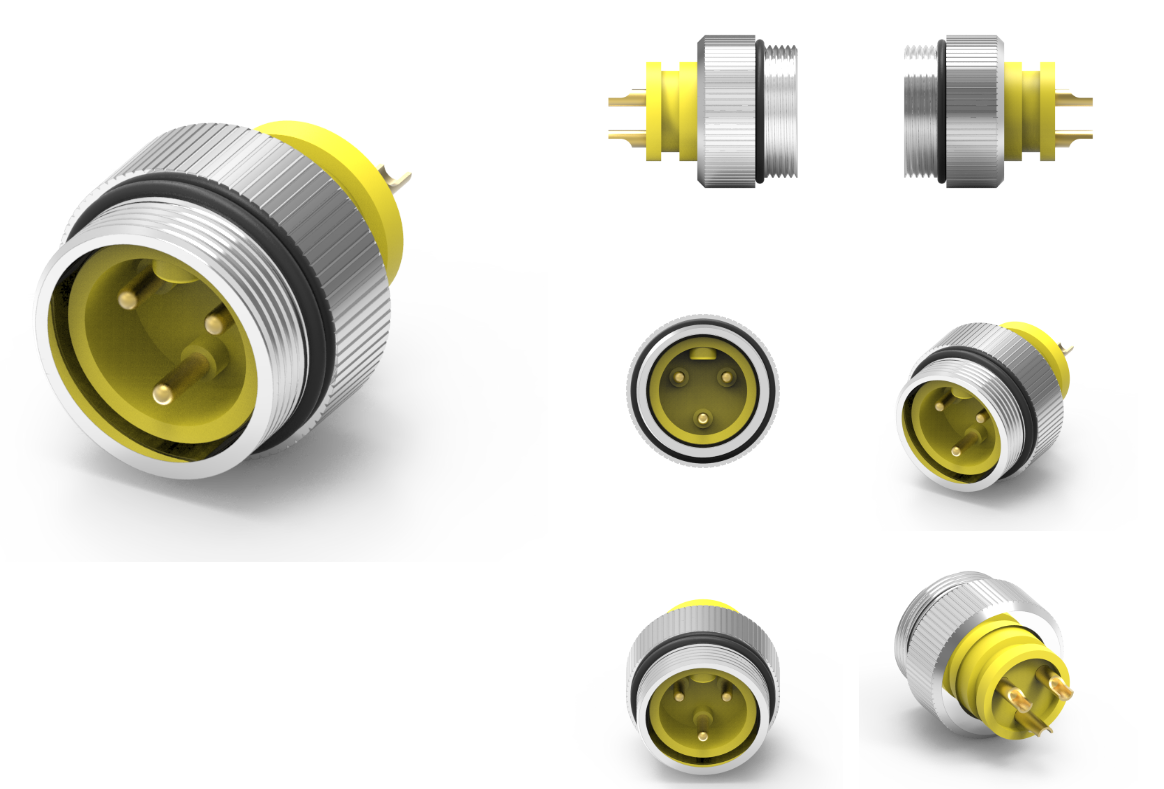

品名:7 8 公头线端成型式防水连接器

1.材料:

1-1.外壳:PBT UL94V-0;颜色:黄色

1-2.触点:黄铜

1-3. 螺母:黄铜

1-4.O型圈:NBR;颜色:黑色

2.完成:

2-1.触点:见表A

底板:镍

2-2. 螺母:镀镍

3.电气规格:

3-1.额定电流:20A

3-2.额定电压:250V

3-3.防水等级:IP68

4.环境:

4-1.0工作温度:-20℃~85℃

品牌:科斯达开关KSDKG

产地:中国东莞

7和8公头线端成型式防水连接器是一种特殊设计的电气连接器,通常用于要求高防护等级和可靠性的应用场合。这类连接器采用成型线端的设计,确保在连接器与导线之间有良好的物理和电气连接,同时能够提供优越的防水性能。

特点

1.线端成型设计:

连接器端子在焊接或压接过程中会与导线形成一种稳定的连接,通常采用专门的工具进行操作,形成良好的电气接触。

这种设计能有效减少接触点的电阻,提升连接的可靠性。

2.防水功能:

该连接器通常具有良好的防水等级(如IP67或更高),依靠密封垫圈(如O型圈)和精确的设计来防止水和灰尘的侵入。

适用于潮湿或恶劣环境,适应性强。

3.多种针脚配置:

提供7针和8针的引脚配置,以适应不同的电气需求和应用场合。

连接器可用于多信号传输,有助于简化布线。

4.耐用材质:

制造材料通常耐高温、耐腐蚀,能在各种工作环境中长时间使用,减小替换频率,降低维护成本。

5.易于安装与维护:

由于线端成型的设计,能够简化连接器的安装过程,并且连接状态一旦确立,便于后续的维护和更换。

应用领域

1.汽车行业:

常用于汽车电气系统中的传感器、灯具和电子控制单元,增强连接的耐用性和稳定性。

2.工业自动化:

在工厂自动化系统中,连接器可以用于机器和控制系统之间的连接,确保信号的稳定传输。

3.通信设备:

在各种通信设备中使用,适用于网络、数据传输等方面,保证数据传输的可靠性。

4.户外设备:

适用于户外电子设备中的电气连接,如监控摄像头、LED 灯具等,能够抵御恶劣天气影响。

使用注意事项

1.焊接与连接:

确保在焊接或安装过程中使用适当的技术和工具,以防止连接不牢固造成的故障。

2.检查完整性:

定期检查连接器的密封性和外观,确保没有老化或破损,防止漏水和短路。

3.操作环境:

了解并遵循连接器的工作温度和压力范围,避免在超出规范的环境中使用。

小结

7和8公头线端成型式防水连接器因其优良的防水性、稳定的电气性能以及高可靠性而被广泛应用于汽车、工业、通信和户外设备等领域。这种连接器在提供安全连接的同时,还能有效应对各种外部环境挑战。如果您有特定的需求或者希望获取更多产品信息,欢迎联系技术员!

Product Name: 7-8 Male Wire End Forming Waterproof Connector

1. Materials:

1-1. Shell: PBT UL94V-0; Color: Yellow

1-2. Contact: Brass

1-3. Nut: Brass

1-4. O-ring: NBR; Color: Black

2. Complete:

2-1. Contact: See Table A

Bottom plate: Nickel

2-2. Nut: Nickel plated

3. Electrical specifications:

3-1. Rated current: 20A

3-2. Rated voltage: 250V

3-3. Waterproof grade: IP68

4. Environment:

4-1.0 Operating temperature:- 20℃~85℃

Brand: Coaster Switch KSDKG

Origin: Dongguan, China

7 and 8 male end molded waterproof connectors are a specially designed electrical connector typically used in applications that require high levels of protection and reliability. This type of connector adopts a molded wire end design, ensuring good physical and electrical connection between the connector and the wire, while providing superior waterproof performance.

characteristic

1. End forming design:

The connector terminal forms a stable connection with the wire during welding or crimping, usually operated with specialized tools to create good electrical contact.

This design can effectively reduce the resistance of the contact points and improve the reliability of the connection.

2. Waterproof function:

This connector typically has a good waterproof rating (such as IP67 or higher), relying on sealing gaskets (such as O-rings) and precise design to prevent water and dust from entering.

Suitable for humid or harsh environments, with strong adaptability.

3. Multiple pin configurations:

Provide 7-pin and 8-pin pin configurations to meet different electrical requirements and application scenarios.

Connectors can be used for multi signal transmission, which helps simplify wiring.

4. Durable material:

Manufacturing materials are usually resistant to high temperatures and corrosion, and can be used for a long time in various working environments, reducing replacement frequency and lowering maintenance costs.

5. Easy to install and maintain:

Due to the design of the wire end forming, the installation process of the connector can be simplified, and once the connection status is established, it is easy for subsequent maintenance and replacement.

application area

1. Automotive industry:

Commonly used in automotive electrical systems for sensors, lighting fixtures, and electronic control units to enhance the durability and stability of connections.

2. Industrial automation:

In factory automation systems, connectors can be used to connect machines and control systems, ensuring stable signal transmission.

3. Communication equipment:

Used in various communication devices, suitable for network and data transmission, ensuring the reliability of data transmission.

4. Outdoor equipment:

Suitable for electrical connections in outdoor electronic devices, such as surveillance cameras, LED lighting fixtures, etc., capable of withstanding adverse weather conditions.

Precautions for use

1. Welding and connection:

Ensure the use of appropriate techniques and tools during welding or installation to prevent malfunctions caused by loose connections.

2. Check integrity:

Regularly check the sealing and appearance of the connector to ensure no aging or damage, and prevent water leakage and short circuits.

3. Operating environment:

Understand and follow the working temperature and pressure range of the connector, and avoid using it in environments that exceed specifications.

Summary

7 and 8 male end molded waterproof connectors are widely used in fields such as automotive, industrial, communication, and outdoor equipment due to their excellent waterproof performance, stable electrical performance, and high reliability. This type of connector not only provides a secure connection, but also effectively addresses various external environmental challenges. If you have specific needs or would like to obtain more product information, please feel free to contact our technicians!