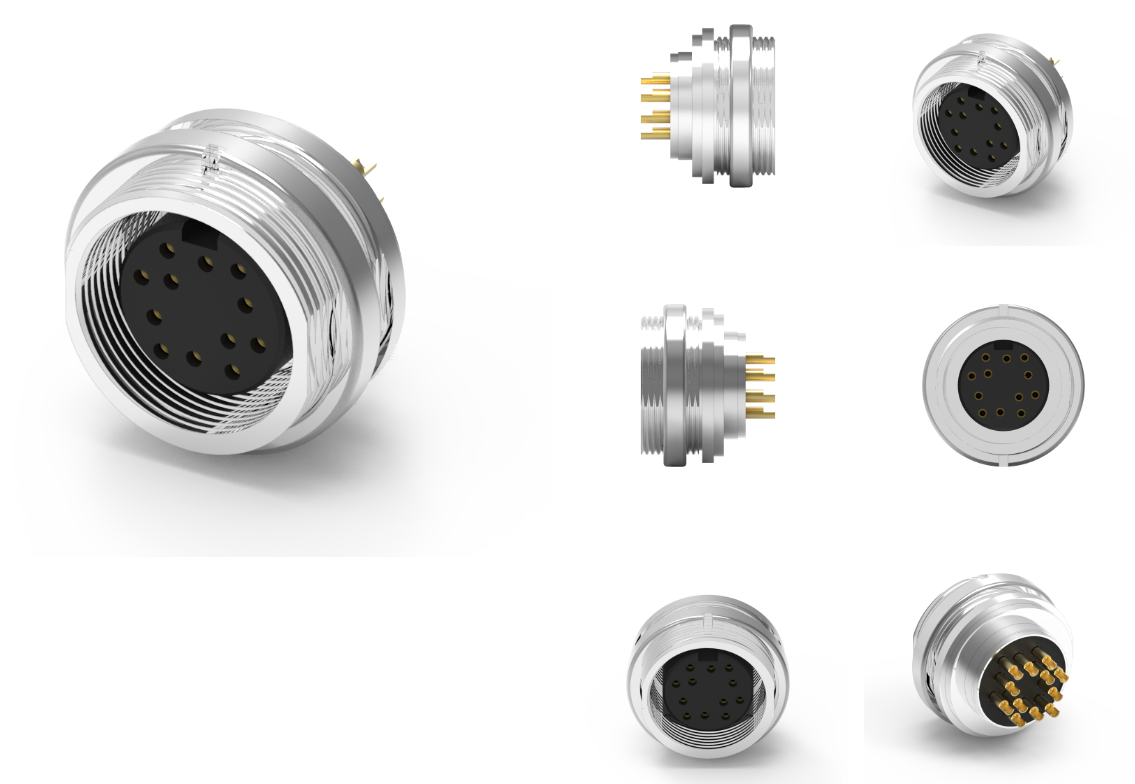

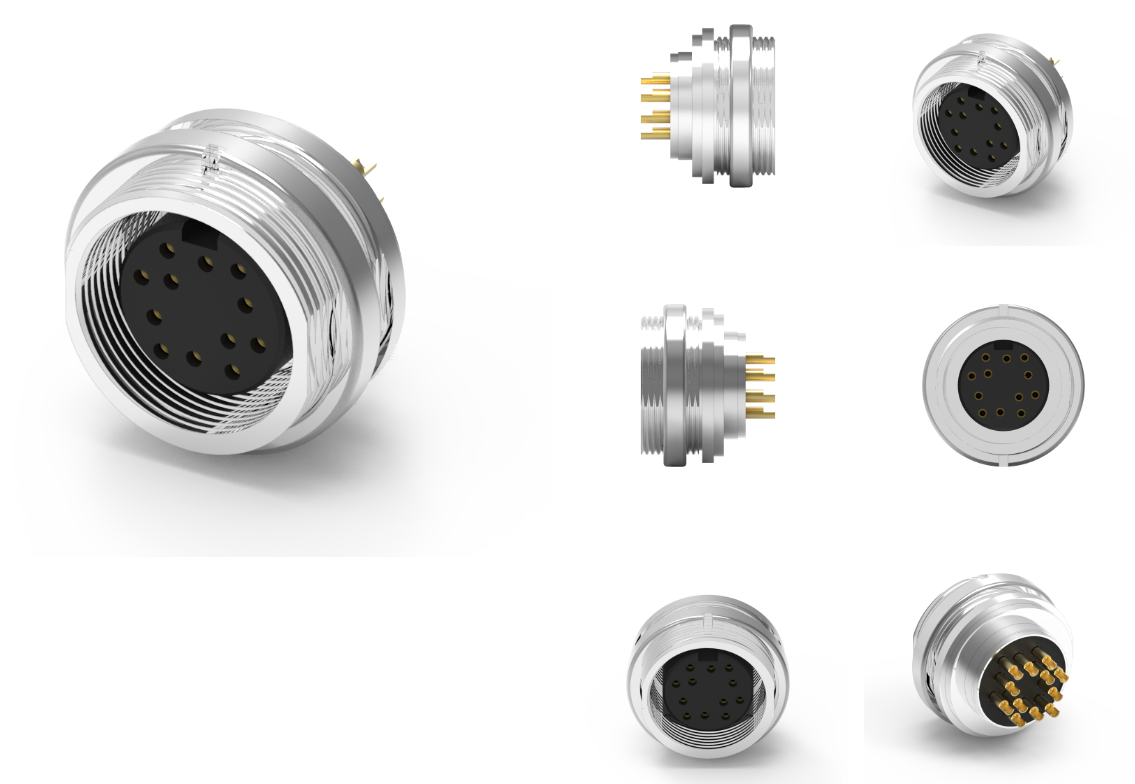

品名:DIN M16 母头前锁焊线式连接器

1.材料

1-1.住房66;颜色:黑色

1-2.触点:黄铜

1-3.外壳:黄铜

1-4.编号:黄铜

2.完成

2-1.触点:镀金

2-2.外壳:镀镍

2-3.编号:镀镍

3.电气规格:

3-1.额定电流:3A

3-2.额定电压:60V

4.环境:

4-1.0工作温度:-40℃~85℃

5.防护等级:IP40

品牌:科斯达开关KSDKG

产地:中国东莞

DIN M16 母头前锁焊线式连接器是一款符合DIN标准的电气连接器,专为在恶劣环境下的可靠电气连接而设计。该连接器采用焊线结构,可以提供更稳固的连接,适合用于工业自动化、设备控制和运输等领域。

主要特点

1.符合DIN标准:

根据DIN M16标准设计,确保与其他标准连接器的兼容性和互换性。

2.焊线式结构:

采用焊线连接方式,在连接时通过焊接将导线与连接器牢牢固定,提供更稳定的电气接触,适合长时间使用。

3.前锁设计:

前锁结构使得连接器在连接后可实现稳固的锁定,有效防止由于震动或其他外力造成的松动,提高了连接的安全性。

4.防水性能:

具备IP67防护等级,能够有效阻挡水、灰尘等物质的侵入,适合于潮湿和多尘的工作环境。

5.多样化引脚配置:

提供多种引脚选项,通常有2至19针的不同配置,可以根据具体的应用需求进行选择。

6.耐用材料:

连接器通常采用高强度塑料和金属材料,耐腐蚀、耐高温,适应各种严苛的环境条件。

7.紧凑设计:

结构紧凑,小巧轻便,适用于空间受限的安装场合。

应用领域

工业自动化:

广泛应用于自动化设备、传感器及控制系统中,保证设备的稳定运行。

汽车和运输:

在车辆和交通工具中提供安全的电气连接,确保各类系统正常工作。

机械设备:

用于各种工业机械的电源和信号传输,确保设备高效运作。

医疗器械:

适用于医疗设备中,为电气连接提供可靠保障。

安装与使用注意事项

1.焊接过程:

在焊接时,确保操作规范,以避免焊接不良或短路现象的发生。

2.环境适应性:

连接器的安装应避免在极端环境下操作,以防止温度或湿度对连接器造成损坏。

3.定期维护:

应定期检查连接器的接口,确保没有水分和灰尘侵入,保持连接的良好状态。

4.使用合适工具:

在进行安装和维护时,应使用专业工具,确保连接器的固定与拆卸都能安全进行。

小结

DIN M16 母头前锁焊线式防水连接器以其优良的防水性能和牢固的焊线结构,为各种电气应用提供了可靠的连接解决方案。适合在各种工业和商业应用中使用,如果您有更具体的应用需求或问题,请联系技术员!

Product Name: DIN M16 Female Head Front Lock Solder Wire Connector

1. Materials

1-1. Housing 66; Color: Black

1-2. Contact: Brass

1-3. Shell: Brass

1-4. Number: Brass

2. Complete

2-1. Contact: Gold plating

2-2. Shell: Nickel plated

2-3. Number: Nickel plating

3. Electrical specifications:

3-1. Rated current: 3A

3-2. Rated voltage: 60V

4. Environment:

4-1.0 Operating temperature:- 40℃~85℃

5. Protection level: IP40

Brand: Coaster Switch KSDKG

Origin: Dongguan, China

The DIN M16 female front locking wire connector is an electrical connector that complies with DIN standards and is designed for reliable electrical connections in harsh environments. This connector adopts a wire bonding structure, which can provide a more stable connection and is suitable for use in industrial automation, equipment control, transportation and other fields.

main features

1. Compliant with DIN standards:

Designed according to DIN M16 standard to ensure compatibility and interchangeability with other standard connectors.

2. Wire bonding structure:

Adopting a wire bonding connection method, the wire is firmly fixed to the connector through welding during connection, providing more stable electrical contact and suitable for long-term use.

3. Front lock design:

The front lock structure enables the connector to achieve stable locking after connection, effectively preventing loosening caused by vibration or other external forces, and improving the safety of the connection.

4. Waterproof performance:

Equipped with an IP67 protection level, it can effectively block the intrusion of substances such as water and dust, making it suitable for humid and dusty working environments.

5. Diversified pin configurations:

Multiple pin options are provided, usually with different configurations ranging from 2 to 19 pins, which can be selected according to specific application requirements.

6. Durable materials:

Connectors are usually made of high-strength plastic and metal materials, which are corrosion-resistant, high-temperature resistant, and suitable for various harsh environmental conditions.

7. Compact design:

Compact in structure, compact and lightweight, suitable for installation in space limited environments.

application area

Industrial automation:

Widely used in automation equipment, sensors, and control systems to ensure stable operation of the equipment.

Automobiles and Transportation:

Provide safe electrical connections in vehicles and transportation to ensure the proper functioning of various systems.

mechanical equipment:

Used for power and signal transmission of various industrial machinery to ensure efficient operation of the equipment.

medical apparatus and instruments:

Suitable for medical equipment, providing reliable protection for electrical connections.

Installation and usage precautions

1. Welding process:

When welding, ensure that the operation is standardized to avoid the occurrence of poor welding or short circuits.

2. Environmental adaptability:

The installation of connectors should avoid operating in extreme environments to prevent damage to the connectors caused by temperature or humidity.

3. Regular maintenance:

The interface of the connector should be checked regularly to ensure that no moisture or dust enters and to maintain a good connection condition.

4. Use appropriate tools:

When installing and maintaining, professional tools should be used to ensure that the fixing and dismantling of connectors can be safely carried out.

Summary

The DIN M16 female head front lock welding wire waterproof connector provides a reliable connection solution for various electrical applications with its excellent waterproof performance and sturdy welding wire structure. Suitable for use in various industrial and commercial applications. If you have more specific application needs or questions, please contact a technician!