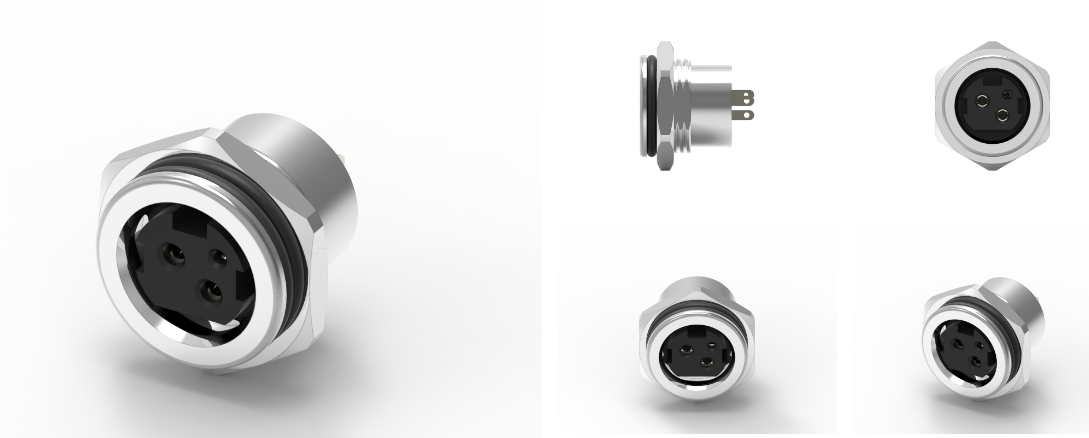

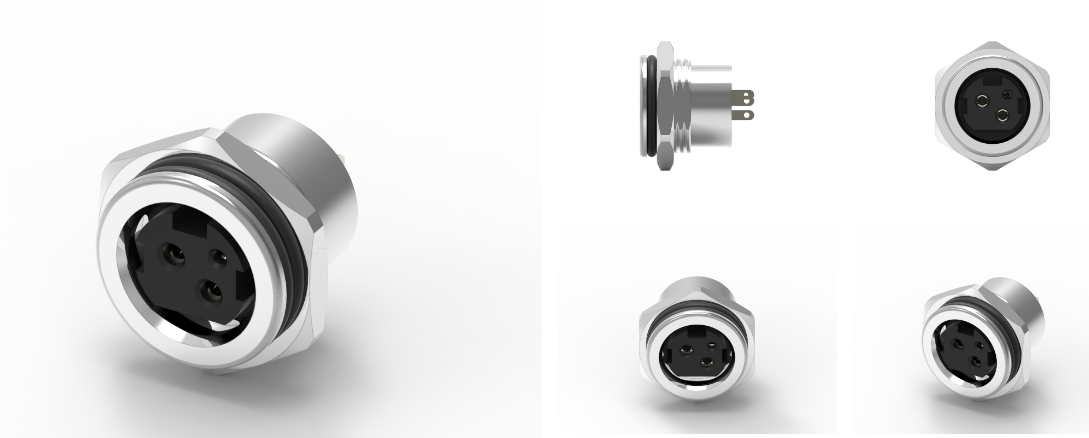

品名:Power DIN 母头后锁焊线式防水连接器

1.材料

1-1. 外壳:PBT UL94V0;颜色:黑色

1-2.触点:磷青铜

1-3.外壳:黄铜

1-4.螺钉:黄铜

1-5.O型圈:硅胶

2.完成:

2-1.联系方式:镀锡镍

2外壳:整体镀镍60u“~100u”

2-3.螺钉:整体镀镍60u“~100u”

3.电气规格:

3-1.额定电流:3针7.5A&1A(引脚3);4针7.5A

3-2.额定电压:最大25V/DC

3-3.防水等级:IP67

4.环境:

4-1.工作温度:-20℃~85℃

品牌:科斯达开关KSDKG

产地:中国东莞

Power DIN 母头后锁焊线式防水连接器是一种专用于电力和信号传输的连接器,具有防水设计和后锁结构,以增强连接的安全性和稳定性。这类连接器通常用于对防水和抗腐蚀有较高要求的应用场合,如户外设备、工业环境及医疗设备等。以下是对该连接器的详细介绍。

特点

1.后锁设计:

连接器具有后锁机制,确保插拔后连接稳定,不易松动。这种设计可以减少振动引起的连接故障,保证连接的安全性。

2.焊线式连接:

使用焊线方法可以确保良好的电气连接,让用户在连接时将导线直接焊接到接头上,提供较高的导电性能。

3.防水功能:

连接器采用防水设计(通常达到IP67或更高防护等级),可以在湿润或恶劣环境中使用,防止水分和污物的侵入,从而保护内部电气元件。

4.耐用材料:

制作材料通常为抗腐蚀的金属和优质塑料,具备良好的机械强度和耐用性,适应各种环境条件。

5.多种针脚配置:

提供多种针脚数量(如3针、5针、7针等),满足不同应用的电流和信号需求。

应用领域

Power DIN 母头后锁焊线式防水连接器的应用广泛,主要包括:

工业设备:

在制造、自动化和控制系统中,作为电源和信号的连接解决方案,确保在恶劣环境下稳定工作。

户外设备:

适用于户外照明、监控设备、交通信号控制等应用领域,确保在雨水和潮湿环境中的安全性。

医疗设备:

在医疗仪器中提供安全的电力传输,确保设备在湿润的环境中也能够顺利运行。

音频和视频设备:

用于专业音频处理和视频设备的连接,保证信号的完整性,同时防止水分和灰尘的影响。

安装与维护建议

焊接连接:

焊线时,请确保焊接工艺正确,以保证电气连接的可靠性。良好的焊接可以避免因接触不良而导致的故障。

防水密封:

使用时请检查密封圈,确保防水设计的有效性。定期维护和更换密封圈,确保其保持良好的密封性能。

定期检查:

定期检查连接器及其接头,确保没有腐蚀、磨损或松动现象,保持良好的电气连接状态。

环境适应性:

尽量避免在超过推荐工作温度或潮湿度的环境中使用,以延长连接器的使用寿命。

总结

Power DIN 母头后锁焊线式防水连接器是一个功能强大且灵活的连接解决方案,具有很高的可靠性和安全性,适合各种高需求的应用。其防水设计和后锁结构,使其在工业、户外和医疗等环境中表现出色。通过适当的安装和定期维护,可以确保连接器的长期稳定性和可靠性。如果您有特定的技术需求或其他疑问,欢迎联系技术员!

Product Name: Power DIN Female Head Rear Lock Solder Wire Waterproof Connector

1. Materials

1-1. Shell: PBT UL94V0; Color: Black

1-2. Contact: phosphor bronze

1-3. Shell: Brass

1-4. Screw: brass

1-5. O-ring: Silicone

2. Complete:

2-1. Contact Information: Tin Nickel Plating

2 Shell: Whole nickel plated 60u "~100u"

2-3. Screw: Whole nickel plated 60u "~100u"

3. Electrical specifications:

3-1. Rated current: 3-pin 7.5A&1A (pin 3); 4-pin 7.5A

3-2. Rated voltage: Maximum 25V/DC

3-3. Waterproof grade: IP67

4. Environment:

4-1. Working temperature:- 20℃~85℃

Brand: Coaster Switch KSDKG

Origin: Dongguan, China

The Power DIN female head rear lock wire waterproof connector is a connector specifically designed for power and signal transmission, with a waterproof design and rear lock structure to enhance the safety and stability of the connection. This type of connector is typically used in applications that require high levels of waterproofing and corrosion resistance, such as outdoor equipment, industrial environments, and medical equipment. The following is a detailed introduction to the connector.

characteristic

1. Rear lock design:

The connector has a rear locking mechanism to ensure stable connection and prevent loosening after insertion and removal. This design can reduce connection failures caused by vibration and ensure the safety of the connection.

2. Solder wire connection:

The use of wire bonding method can ensure good electrical connection, allowing users to directly solder wires to the joint during connection, providing high conductivity.

3. Waterproof function:

The connector adopts a waterproof design (usually reaching IP67 or higher protection level), which can be used in humid or harsh environments to prevent the intrusion of moisture and dirt, thereby protecting internal electrical components.

4. Durable materials:

The production materials are usually corrosion-resistant metals and high-quality plastics, which have good mechanical strength and durability, and can adapt to various environmental conditions.

5. Multiple pin configurations:

Provide multiple pin numbers (such as 3, 5, 7, etc.) to meet the current and signal requirements of different applications.

application area

The application of Power DIN female head rear lock welding wire waterproof connectors is widely used, mainly including:

Industrial equipment:

As a connection solution for power and signals in manufacturing, automation, and control systems, it ensures stable operation in harsh environments.

Outdoor equipment:

Suitable for outdoor lighting, monitoring equipment, traffic signal control and other application fields, ensuring safety in rainy and humid environments.

Medical equipment:

Provide safe power transmission in medical equipment to ensure smooth operation even in humid environments.

Audio and video equipment:

Used for connecting professional audio processing and video equipment, ensuring signal integrity while preventing the influence of moisture and dust.

Installation and maintenance recommendations

Welding connection:

When welding wires, please ensure that the welding process is correct to ensure the reliability of electrical connections. Good welding can prevent malfunctions caused by poor contact.

Waterproof sealing:

Please check the sealing ring during use to ensure the effectiveness of the waterproof design. Regularly maintain and replace the sealing ring to ensure its good sealing performance.

Regular inspection:

Regularly inspect connectors and their joints to ensure that there is no corrosion, wear, or looseness, and maintain good electrical connection.

Environmental adaptability:

Try to avoid using connectors in environments that exceed recommended working temperatures or humidity levels to extend their lifespan.

summary

The Power DIN female head rear lock solder wire waterproof connector is a powerful and flexible connection solution with high reliability and safety, suitable for various high demand applications. Its waterproof design and rear lock structure make it perform well in industrial, outdoor, and medical environments. By proper installation and regular maintenance, the long-term stability and reliability of the connector can be ensured. If you have specific technical requirements or other questions, please feel free to contact a technician!