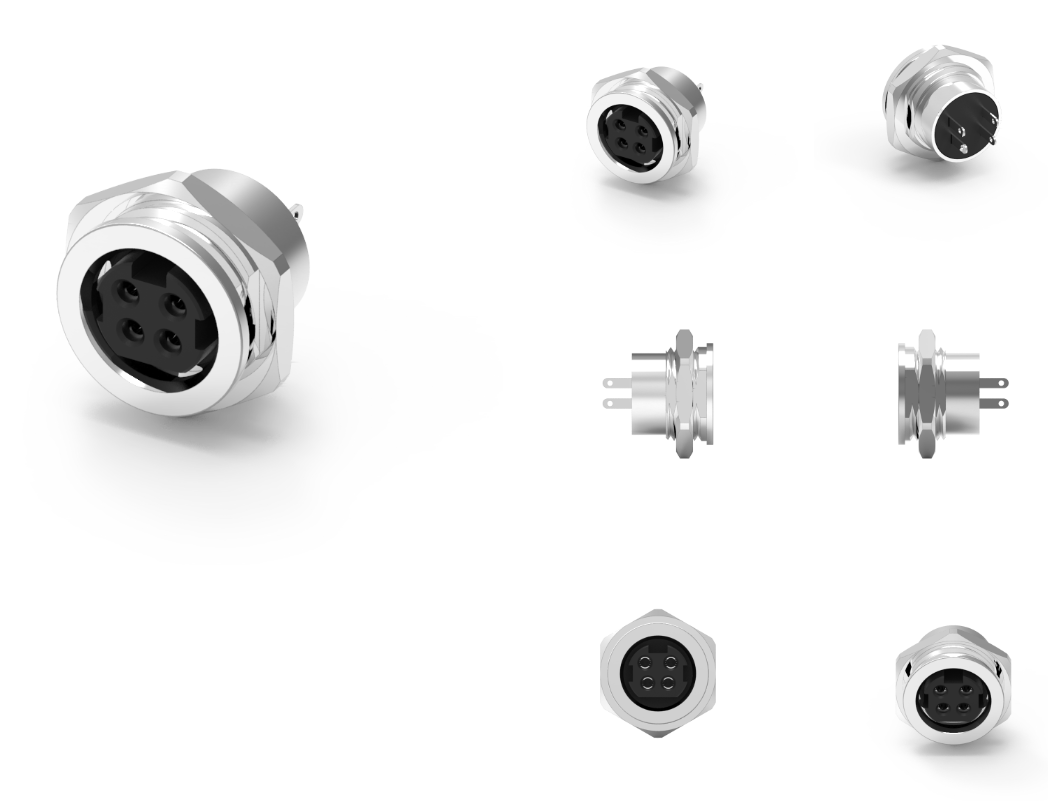

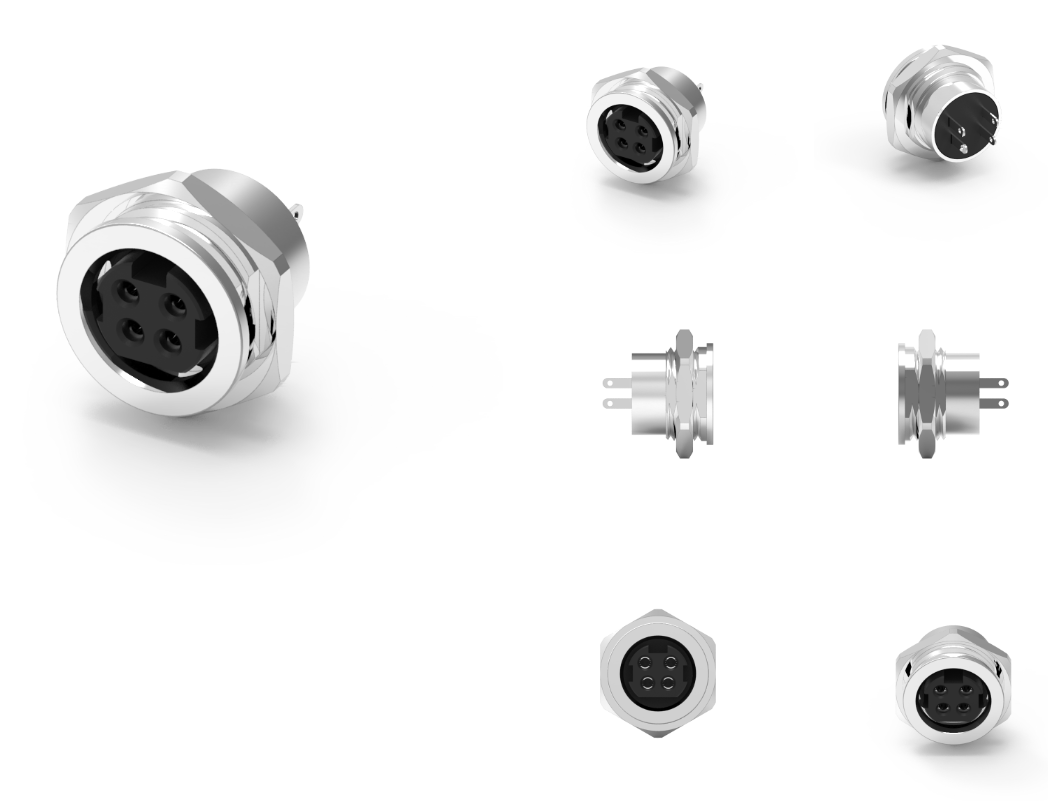

品名:Power DIN 母头后锁焊线式连接器

1.材料:

1-1.外壳:PBT UL94V0;颜色:黑色

1-2.触点:磷青铜

1-3.外壳:黄铜

1-4.螺钉:黄铜

2.完成:

2-1.联系方式:镀锡镍

2-2.外壳:整体镀镍60u“~100”

2-3.螺钉:整体镀镍60u“~100”

3.电气规格:

3-1.额定电流:7.5A&1A

3-2.额定电压:最大20V/DC

4.环境:

4-1.工作温度:-20℃~85℃

品牌:科斯达开关KSDKG

产地:中国东莞

Power DIN 母头后锁焊线式连接器是一种常见的电源和信号连接器,广泛应用于工业、消费电子、音频设备和自动化系统等领域。其设计旨在提供稳定的连接和易于安装的特点。以下是对这种连接器的详尽介绍:

特点

1.后锁设计:

连接器采用后锁机制,这种设计可确保连接在插入后能够牢固固定,减少因振动或机械冲击导致的松动,提高了连接的稳固性和可靠性。

2.焊线式连接:

焊线设计允许用户将线缆直接焊接到连接器的引脚上,这种方法确保了高导电性和稳定的电气性能,同时也减少了连接器松动的可能性。

3.多针脚配置:

根据具体需求,Power DIN 母头连接器提供多种针脚选项(如3针、5针、7针等),满足不同电源和信号传输的需求。

4.易于安装:

后锁和焊线的设计使其相对容易安装,特别是在设备制造或维护过程中,其结构简化了安装步骤。

5.耐用性与可靠性:

通常采用高质量的材料制造,如镀金或镀银的金属接触点,确保良好的导电性能和耐腐蚀性。

应用领域

Power DIN 母头后锁焊线式连接器在多个领域中有着广泛的应用,包括但不限于:

音频设备:

用于音响系统、调音台、乐器等设备的电源和信号连接,确保音频信号的高质量传输。

工业自动化:

在工业控制系统、传感器和执行器中进行电源和信号的连接,提供稳定的操作性能。

医疗设备:

用于医疗仪器和设备中,确保其在运行过程中电源和信号的安全性和稳定性。

消费电子产品:

在一些消费电子产品(如音响、高清视频设备等)中使用,兼顾美观和实用。

安装与维护建议

焊接注意事项:

焊接时应确保焊接质量,避免冷焊或虚焊。在焊接过程中,应注意焊接温度和时间,防止损坏连接器。

定期检查:

定期检查连接器的连接状态,确保没有松动、腐蚀或其他损坏。保持良好的电气连接可以延长设备的使用寿命。

使用环境:

确保连接器符合推荐的使用环境条件,例如温度、湿度等,避免在极端环境下使用,以维护连接器的性能。

适用线材:

使用符合规格要求的线材,以确保焊接的安全性和可靠性,选择合适的导线尺寸和材料以匹配连接器。

总结

Power DIN 母头后锁焊线式连接器以其优越的设计理念和可靠的性能,在多个行业中得到了广泛应用。它能够确保可靠的电源和信号连接,是一款性价比高的连接解决方案。通过合理的安装和维护,可以最大限度地发挥其效用,确保设备在各种环境下的稳定运行。如果您有特定的技术需求或其他疑问,欢迎联系技术员!

Product Name: Power DIN Female Head Rear Lock Solder Wire Connector

1. Materials:

1-1. Shell: PBT UL94V0; Color: Black

1-2. Contact: phosphor bronze

1-3. Shell: Brass

1-4. Screw: brass

2. Complete:

2-1. Contact Information: Tin Nickel Plating

2-2. Shell: Whole nickel plated 60u "~100"

2-3. Screw: Whole nickel plated 60u "~100"

3. Electrical specifications:

3-1. Rated current: 7.5A&1A

3-2. Rated voltage: Maximum 20V/DC

4. Environment:

4-1. Working temperature:- 20℃~85℃

Brand: Coaster Switch KSDKG

Origin: Dongguan, China

Power DIN female head rear locking wire connector is a common power and signal connector, widely used in industrial, consumer electronics, audio equipment, automation systems and other fields. Its design aims to provide stable connections and easy installation features. The following is a detailed introduction to this type of connector:

characteristic

1. Rear lock design:

The connector adopts a rear locking mechanism, which ensures that the connection can be firmly fixed after insertion, reduces looseness caused by vibration or mechanical impact, and improves the stability and reliability of the connection.

2. Solder wire connection:

Solder wire design allows users to directly solder cables to the pins of connectors, ensuring high conductivity and stable electrical performance while reducing the possibility of connector looseness.

3. Multi pin configuration:

According to specific requirements, the Power DIN female connector offers multiple pin options (such as 3-pin, 5-pin, 7-pin, etc.) to meet the needs of different power sources and signal transmission.

4. Easy to install:

The design of the rear lock and welding wire makes it relatively easy to install, especially during equipment manufacturing or maintenance, and its structure simplifies the installation steps.

5. Durability and reliability:

High quality materials such as gold-plated or silver plated metal contact points are usually used to ensure good conductivity and corrosion resistance.

application area

The Power DIN female end locking wire connector has a wide range of applications in multiple fields, including but not limited to:

Audio equipment:

Used for power and signal connections in audio systems, mixing consoles, musical instruments, and other equipment to ensure high-quality transmission of audio signals.

Industrial automation:

Connect power and signals in industrial control systems, sensors, and actuators to provide stable operational performance.

Medical equipment:

Used in medical instruments and equipment to ensure the safety and stability of power and signals during operation.

Consumer electronics products:

Used in some consumer electronics products (such as speakers, high-definition video equipment, etc.), balancing aesthetics and practicality.

Installation and maintenance recommendations

Welding precautions:

During welding, the welding quality should be ensured to avoid cold welding or virtual welding. During the welding process, attention should be paid to the welding temperature and time to prevent damage to the connector.

Regular inspection:

Regularly check the connection status of the connector to ensure there is no looseness, corrosion, or other damage. Maintaining good electrical connections can extend the lifespan of equipment.

Usage environment:

Ensure that the connector meets the recommended environmental conditions for use, such as temperature, humidity, etc., and avoid use in extreme environments to maintain the performance of the connector.

Applicable wires:

Use wires that meet the specifications to ensure the safety and reliability of welding, and select appropriate wire sizes and materials to match the connector.

summary

The Power DIN female end locking wire connector has been widely used in multiple industries due to its superior design concept and reliable performance. It can ensure reliable power and signal connections, making it a cost-effective connection solution. By proper installation and maintenance, it is possible to maximize its effectiveness and ensure stable operation of the equipment in various environments. If you have specific technical requirements or other questions, please feel free to contact a technician!